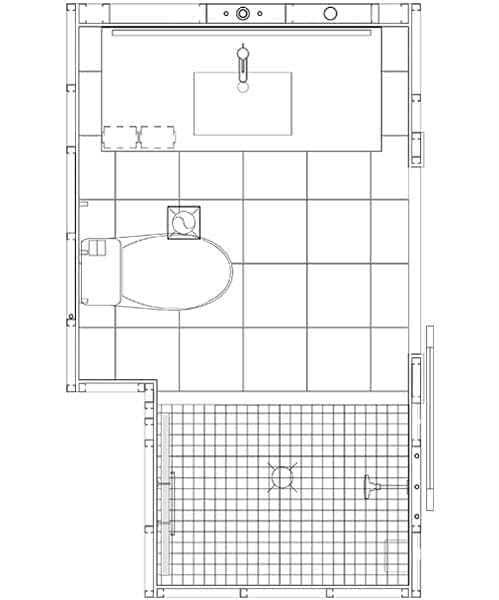

Transform Your Construction With Modular

B&T specializes in manufacturing bathroom Pods, kitchen Pods and modular steel frame construction products. We serve the residential, light commercial, hospitality and the multifamily construction market. We proudly use the FRAMECAD steel frame systems to manufacture our products in a factory controlled environment. We dramatically reduce our customers construction projects schedules – by as much as 30%. We deliver fully inspected products directly to your job site – completely eliminating punch lists and the delays that come with them. We deliver the right product to your site, on-time and on budget – every time. Reduced cost, improved quality and reduced build times.

Our process

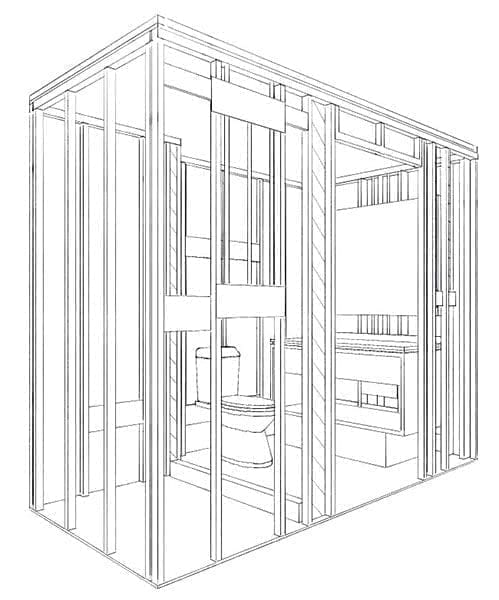

B&T Manufacturing uses FRAMECAD’s accurate steel frame system which enables architectural and design flexibility that is cost efficient, sustainable, durable and safe with exceptional resistance to fire, corrosion and pests. Steel framing lasts longer, is light and easy to transport and has been proven to withstand severe bush fire temperatures of more than 1000°C. It has a structural integrity that means it stays straight, true and most importantly, safe.

Quality

Let our expert staff of professionals help you design your modular steel frame construction or bathroom pod project. Fabricated in a controlled Factory environment. All components inspected and certified to meet your requirements – before shipping.

Manufacturing Process

Once your design is approved, B&T can provide a first article prototype for your inspection before proceeding with the full order. We use only top-quality materials to meet your demanding standards. Our expert staff will ensure your products are ready to integrate into your project when they arrive on site.

Delivery

Completed products are shrink-wrapped in industrial-strength material for transport by truck to your site. B&T can manufacture your products while on-site construction is still going on and deliver the products as you need them significantly reducing your construction time and costs. As soon as you are ready we deliver the product to you – ready to assemble.

Installation

Our convenient product kitting and packaging are put together in the exact sequence you will need to assemble them on site – simplifying construction and reducing labor, time and costs. Whether you are using our modular steel frame products or modular pod units B&T can assist with your installation and assembly needs.

Project timeline

Prefabricated pod and modular steel frame product design integration

Project Owners, Architects, Managers and B&T coordinate details of connections for electrical, plumbing and mechanical systems for factory production

Prototype & certification approval

Third party approvals are obtained and a prototype of the production can be reviewed

Prefabricated pod and modular steel frame product design integration

Modular systems are manufactured and inspected at our factory location and then prepared for the staged construction site delivery

Installation training & commissioning witness

B&T’s team will oversee the first series of prefab building pods being installed at the multistory construction site, and provide training on any installation questions, and support the building inspection and commissioning process